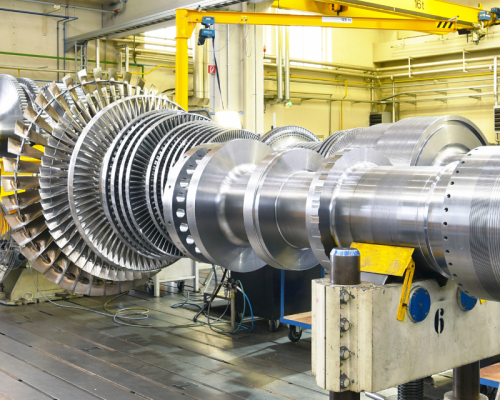

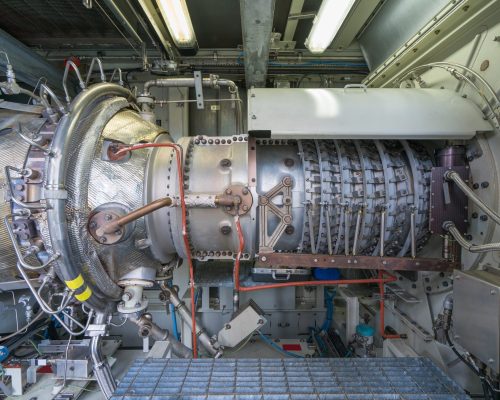

Gas turbines are pivotal to the success of many companies in the LNG industry and many sectors of Power Generation. These turbines are complex and designed to handle an immense workload but can be temperamental. For many, the answer to temperamental machines is redundancy and having additional turbines that can be put online if a primary turbine needs to shut down unexpectedly. Redundancy is a good safety measure to protect productivity, but wouldn’t it be better if you only needed spare machines for planned maintenance and didn’t have the added stress of an emergency disrupting your day at all?

We believe in exactly that! We have developed a solution to make your life and your team’s life less stressful with accurate, detailed, and reliable data. That’s why we developed the SETPOINT® solution to measure crucial vibration and performance data that provides you with a complete understanding of exactly what’s happening with your machines.