Accurate and reliable monitoring of steam turbines is critical for the safety and well-being of your staff and facility. Providing a safe work environment is necessary and goes beyond the requirements to comply with regional mandates. One of our goals is to help keep your team and facility safe, and with 80 years of experience in machine monitoring, we know exactly what it takes to make this happen.

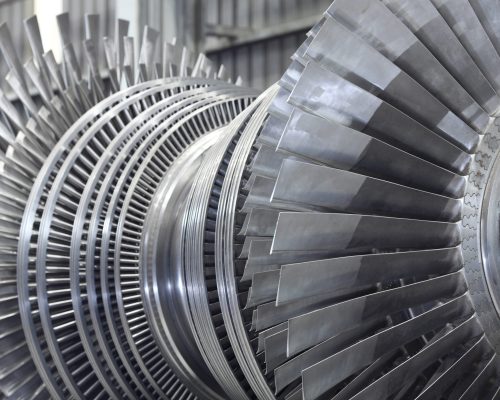

SETPOINT® is a complete machine protection or Condition Monitoring Solution for your steam turbines that measures crucial factors on your turbines, including case expansion, differential expansion, eccentricity, phase reference/speed, casing vibration, axial displacement, shaft and bearing vibration, and more, to ensure your turbines are safe and performing at maximum potential.