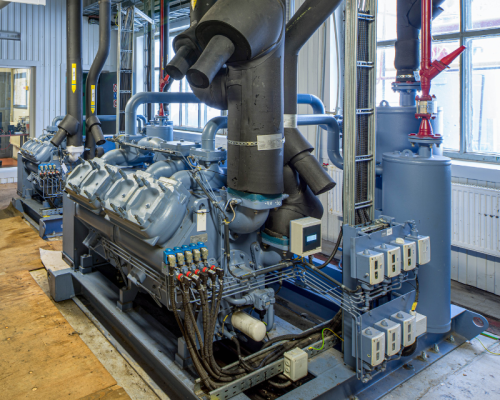

Reciprocating Compressors are complex machines that require precise and careful monitoring to be sure they are running at optimal performance. These intricate machines can become costly and dangerous if an issue occurs, and it makes having a reliable monitoring system even more important.

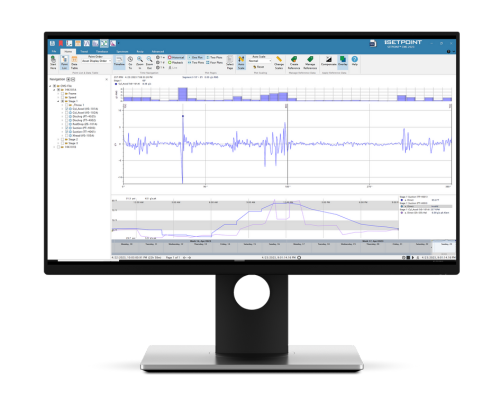

The SETPOINT® Solution is designed with advanced capabilities to ensure that your reciprocating compressors are running safely and meeting the level of productivity you need. SETPOINT® monitors everything from case vibration, bearing looseness, piston vibration, crank vibration, and crank angle to pressure fluctuations, outlet temperatures, potential leaks, and much more. SETPOINT® is the solution you need to confidently know that you are getting the most from your reciprocating equipment.